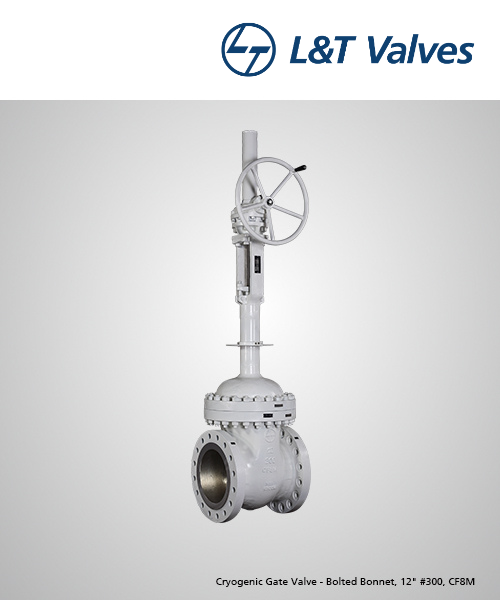

Product Description

Design Valve Types Available:

-

Gate Valves: Size 2″ to 54″ (50 mm to 1350 mm), ASME Class 150 to 2500

-

Design Standards: API 600, ASME B16.34, BS 6364, ISO 28921

-

-

Globe Valves: Size 2″ to 24″ (50 mm to 600 mm), ASME Class 150 to 600

-

Design Standards: API 623, BS 1873, ASME B16.34, BS 6364, ISO 28921

-

-

Check Valves: Size 2″ to 36″ (50 mm to 900 mm), ASME Class 150 to 2500

-

Design Standards: API 594, BS 1868, ASME B16.34, BS 6364, ISO 28921

-

End Connection:

-

Flanged Ends (ASME B16.5)

-

Butt Weld Ends (BW)

-

Other connection types available upon request

Compliance & Testing:

-

Fugitive Emissions: Complies with ISO 15848-1 (Endurance Class CO2, Tightness Class BH)

-

Tested at -196°C per BS 6364, in-house facility for valves up to 60″

-

SIL3 Safety Integrity Level for automated valves

-

Successfully tested to Shell Design Validation Test Procedure 77/300 (witnessed by Shell Inspectors)

-

Optional Tests: EN 12567 Annex A (Thermal Shock Test) and Annex B (Endurance Test)

-

Inspection & Testing in accordance with API 598

Pressure & Temperature Capability:

-

Temperature: down to -320°F (-196°C)

-

Pressure: up to 750 psi (52 bar) depending on class

-

ASME Class 150 to 2500 (varies by valve type)

Main Body Materials:

-

Carbon Steel: LCB, LCC, LC3, LF2

-

Stainless Steel: CF8, CF8M, CF3, CF3M, F304, F304L, F316, F316L

-

Available in a wide range of metallurgies for specific low-temperature applications

Drive Options:

-

Manual Handle

-

Bevel Gear

-

Electric Actuator

-

Pneumatic Actuator

Key Features:

-

Bonnet extension/extension column keeps packing rings within safe temperature range

-

Thermal stabilisation of body and obturator to ensure dimensional stability during temperature cycles

-

Cavity relief pressure arrangement to prevent thermal locking

-

Seat and disc hardfaced to prevent seizing and galling

-

Engineered for LNG, LPG, and cryogenic hydrocarbon service

-

Multiple actuation options for remote and automated operation

-

ValvTrac™ RFID tags for reliable digital traceability